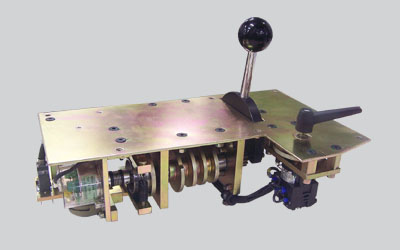

Master Controller is manually operated equipment that comprises the control elements required for driving and braking, as well as for controlling the auxiliary function of traction rail vehicles from Driver's desk. Master controller is suitable for use on 3-phase, 25KV, AC Locomotives as well as in the Driving Cars of EMUs.

| Description | Values |

|---|---|

| Drive direction selector (Reverser) Switch |

|

| Brake / drive handle |

|

| Auxiliary Switch | |

| No of auxiliary contacts actuated by Brake / Drive handle | 4 units |

| Auxiliary Switch: Rated voltage | 72V (Tolerance +25% & -30%) |

| Mechanical life of Auxiliary Switch | 10 million switching cycles |

| Angle Converter | |

| Input Power supply | 24VDC (tolerance +25% to -30%) / 30mA |

| Angle Range | -120° to +120° |

| Output current (mA) | 2 to 20 |

| Dielectric Test Voltage(AC 50Hz for 1min) |

Live parts against ground : 1500V Auxiliary contact against ground : 1500V Across open auxiliary contacts : 2000V |

| Operating temperature range of equipment | - 25°C to + 70°C |

| Weight | Approx. 10 Kg |